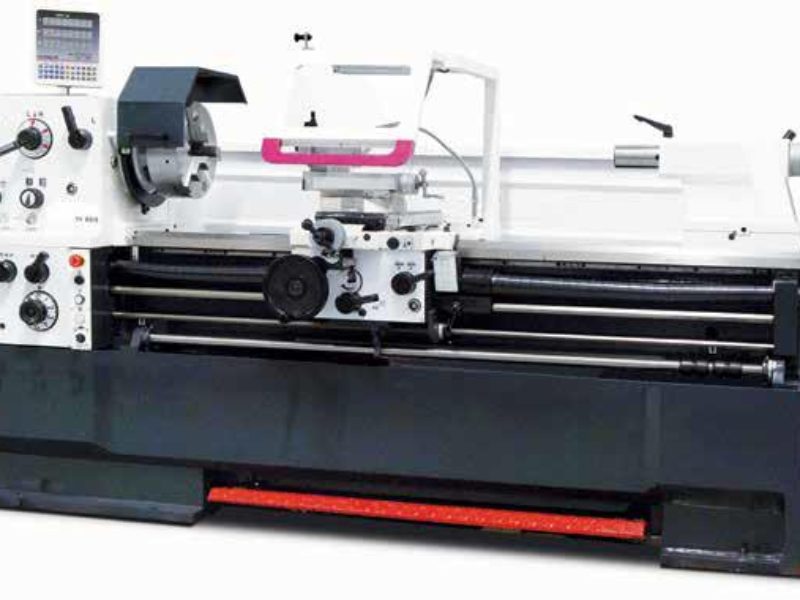

Excel Heavy Duty Precision Lathe Models TH5610 TH5615 TH5620 TH5630

Excel Heavy Duty Precision Lathe Models TH5610 TH5615 TH5620 TH5630

Specification

Electrical Connection 400 V / 3 Ph ~ 50Hz

Total Connected load 8.5 kW

Drive Power spindle motor 7.5 kW

Centre height 280 mm

Between centres 1000mm, 1500mm, 2000mm, 3000mm.

Swing over bed 560 mm

Swing over cross slide 355 mm

Turning in the gap 790 mm

Length in the gap 150 mm

Bed width 350 mm

Spindle speed 25-1600 min-1

Number of steps 12

Spindle taper MK 7

Spindle taper Camlock DIN ISO 702-2 D1-8

Spindle bore, 80 mm

Traverse top slide 130 mm

Traverse cross slide 310 mm

Pitch Metric (47) 0.2-14mm/rev

Pitch Inch (60) 2-112TPI

Modular Threads (34) 0.1-7 MP

Diametrical Threads (50) 4-112 DP

Longitudinal Feeds (35) 0.059-1.646mm/rev

Cross Feeds (35) 0.020-0.573mm/rev

Toolholder Seat height (max) 25 x 25 mm

Tailstock MK 5

Tailstock – Quill 180 mm

Dims cm(L x W x H) 234x115x146 284x115x146 334x115x146 434x115x146

Weight 2302 kg 2720 kg 3000 kg

FEATURES

� Hardened & ground Spindle with 3 adjustable precision Taper Roller Bearings

� Guaranteed concentricity precision of the Spindle Nose less than 0.015mm

� Sealed Quick Change Gear box

� Lathe Bed made from a single block of Meehanite Cast Iron

� Removable Gap-Bed

� Hardened & ground Bed Slide Ways

� Central lubrication system in the tool slide

� Bar with 4 trip dogs for longitudinal movement

� Manufactured according to DIN 8606 (Toolmakers Precision).

� Coolant system with separate coolant tank, level indicator and oil separator; easy for emptying and cleaning.

� Right-left hand rotation can be switched with the help of the Indexing Lever

� Cover for Lead Screw

� Lo Volt release, emergency stop button & protective Motor Switch

Included as standard:

� 315mm 3 Jaw Chuck

� 400mm 4 Jaw Chuck

� 16-95mm Follow Rest

� 450mm Face Plate

� 20-165mm Steady Rest

� Coolant System

� Rear Splash Guard

� Machine Lamp

� Dial Indicator

� Operating Tools

� Spindle Footbrake

� Electrically Interlocked Chuck Guard

� Toolpost Chip Guard

� 2 Axis DRO