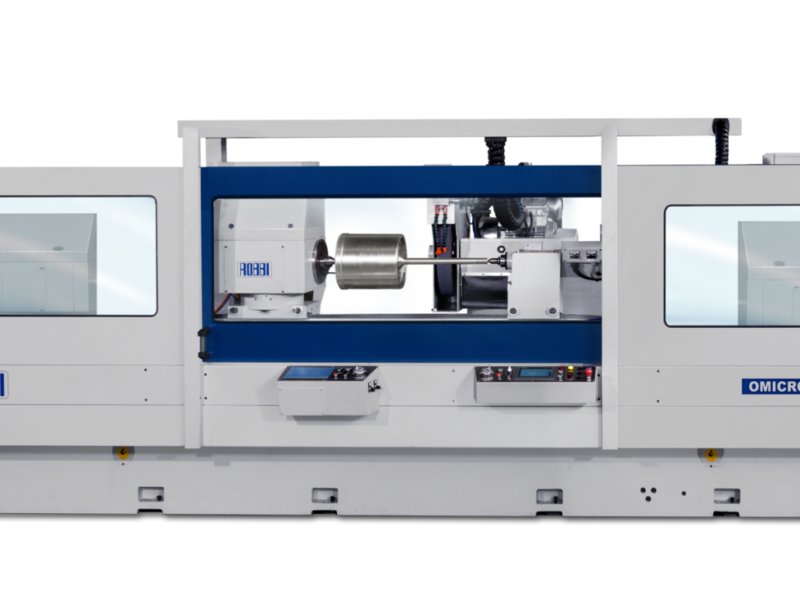

Robbi Omicron CNC 36 Series Universal Grinders

P.O.A

Robbi Omicron CNC 36 Series Universal Grinding Machines

Description

ROBBI CNC Universal Cylindrical Grinders. The CNC versions were developed in response to needs for medium-high production volumes. Equipped with the latest-generation of SIEMENS 840D sl control system. The work cycle can be optimised in-process with geometrical and working parameters.

Machine Specifications | CNC 3606 |

| Maximum distance between centres | 630mm |

| Maximum grinding length | 630mm |

| Height of centres over table | 180mm |

| Swing over table | 355mm |

| CNC 3610 | |

| Maximum distance between centres | 1030mm |

| Maximum grinding length | 1030mm |

| Height of centres over table | 180mm |

| Swing over table | 355mm |

| CNC 3615 | |

| Maximum distance between centres | 1530mm |

| Maximum grinding length | 1530mm |

| Height of centres over table | 180mm |

| Swing over table | 355mm |

| CNC 3620 | |

| Maximum distance between centres | 2030mm |

| Maximum grinding length | 2030mm |

| Height of centres over table | 180mm |

| Swing over table | 355mm |

Machine is equipped with: |

| CNC SIEMENS SINUMERIK 840D sl, PCU 50.3 |

| Wheelhead and table automatic electronic feed controlled by motors brushless |

| Incremental optic rule for micro positioning of wheelhead |

| Re-circulating ball screw with preloaded nut for wheelhead and table movement |

| Anti-friction material on wheelhead guides |

| Electric installation, in cooled cabinet |

| Hydraulic unit for tailstock control |

| Pneumatic unit |

| Centralised lubrication |

| Table manual swivelling system for taper grinding with dial gauge |

Standard Equipment |

| Coolant magnet cleaner and coolant paper roll cleaner complete with electric equipment and coolant tank |

| Straight wheel dressing unit (diamond optional) mounted on tailstock |

| Grinding wheel diam. mm. 450, thickness mm. 80, hole mm. 127 |

| Wheel balancing arbor |

| Wheel extractor |

| Additional pulley for wheel motor |

| 2 hard metal tipped centres |

| Set of levelling screws and plates |

| 2 cloth bellows for protection of table guides |

| Sliding doors |

| Set of service spanners & Set of hexagonal spanners |

| 5 Kg. oil for wheel spindle lubrication & 5 Kg. oil for guide lubricating |

| Instruction manual |