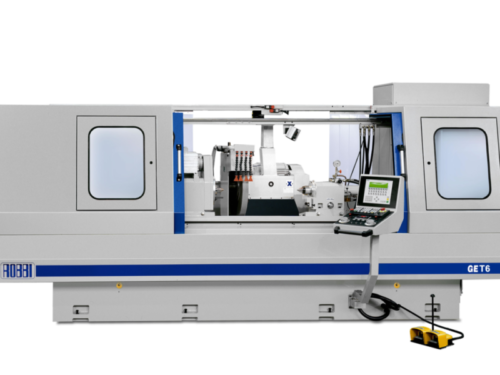

DESCRIPTION & SPECIFICATIONS

Travelling column with stabilised Meehanite cast iron structure. All the machine axes feature full grip hydrostatic slideways along the entire travel. The spindle line has a Mackensen hydrodynamic bearing on the front and a pair of pre-loaded precision ball bearings on the rear. DELTA MAXI Series travelling column grinding machines are available in 9 models with grindable surfaces from 1200 x 750mm to 3000 x 1100mm with 2 different levels of automation: – NC or CNC.

SPECIFICATION

| Working Capacity | |

| max. grinding length | 2000mm |

| max. grinding width (with a 76 mm wheel) | 750mm |

| max. grinding width (with a 100 mm wheel) | 775mm |

| max. Distance from table plane to spindle axis | 900mm |

| Table – X Axis | |

| table length | 2000mm |

| table width | 600mm |

| T- slots available | 4 |

| T-slot width | 18 mm |

| T-slots centre distance | 125 mm |

| working speed range (infinitely variable) | 0÷40m/min |

| max. travel distance | 2300mm |

| max. admissible load | 3000kg |

| Column – Y Axis | |

| max. travel distance | 675mm |

| working speed range (infinitely variable) | 0÷4 m/min |

| min. programmable increment | 0.001mm |

| Wheelhead – Z Axis | |

| spindle speed (50 Hz) | 1450rpm |

| spindle speed range (infinitely variable) | 1000÷2000rpm |

| with digital inverter option | |

| max. speed | 1.5m/min |

| min. programmable increment | 0.001 m |

| Grinding Wheel | |

| Standard wheel dimensions (ODxWxBD) | 400 x 76 x 127mm |

| wheel recess dimensions (both sides) | 220 x 10/15mm |

| Max. wheel dimensions (ODxWxBD) | 400 x 100 x 127mm |

| wheel recess dimensions (both sides) | 220 x 20/30mm |

| Spindle Motor ~ Installed Power | 18.5kW |

| Hydraulic Motor ~ Installed Power | 7.5kW |

| Machine Weight ~ approximate net weight of the machine | 11500kg |

| Machine Voltage ~Standard machine voltage | 400V / 3 phase / 50 Hz + neutral + ground |

| Machine Colour ~Standard machine colour | RAL 5018 (turquoise) and 7032 (light grey) |

STANDARD FEATURES

| Standard grinding wheel (400 x 76 x 127-220 x 10/15 mm) |

| Wheel holder flange |

| Wheel locking nut |

| Wheel extractor |

| Balancer crankshaft |

| Over the wheel dressing system (excluding diamond) |

| Table mounted single point dressing attachment (excluding diamond) |

| Full machine guarding enclosure |

| Set of tools |

| Set of documentation (in English) including: |

| Instructions Book, Test Certificate (according to ISO 1986 standard), CE Conformity Declaration |

| Hydraulic unit (excluding hydraulic oil) |

| Heat exchanger unit for hydraulic unit |

| Compact Plus NC fully automatic unit |

| Electrical cabinet |

Travelling Column with stabilised Meehanite cast-iron structure: With the travelling column, the wheel head is fully supported.

- maximum rigidity

- removes a large amount of material

- flatness guaranteed

Hydrostatic support for all axes with full grip slideways. All the machine axles feature full grip hydrostatic slideways; therefore, the table always rests on the basement for the entire longitudinal travel; the same criterion applies to the column and the wheelhead. This involves:

- absence of anti-friction material (turcite)

- zero friction (optimal exploitation of the installed power)

- zero wear (geometry guaranteed for a long period of time)

- No stick-slip. Extremely smooth movements

The proof? Pressing the table with one finger is all it takes to move considerable loads. See the videos…