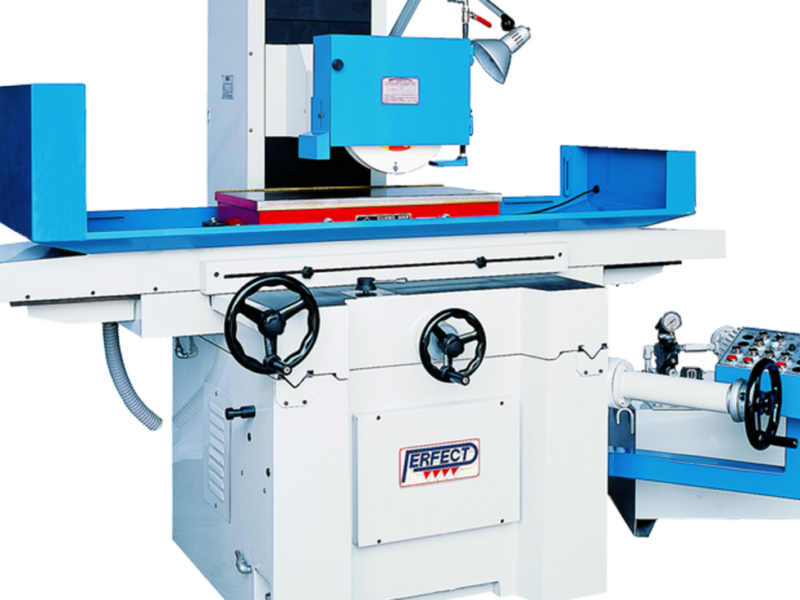

DESCRIPTION & SPECIFICATIONS

Major parts of the PERFECT are manufactured from high quality cast iron combined with an outstanding structural design. Major parts are stress relieved to ensure maximum rigidity, stability and machining accuracy. H Series machines are longitudinal by hydraulic and cross feed/vertical axis are manual. AH Series machines are auto cross feed, longitudinal by Hydraulic and vertical axis is manual.

SPECIFICATION |

PFG 2550H/AH |

| Table size | 250 x 500mm |

| Max. Grinding surface | 250 x 500mm |

| Max. distance centre of spindle to table | 500mm |

| Table speed | 5 ~ 25m/min |

| Table guideway | V & Flat way |

| Auto. Cross feed increment approx. | Manual (H Model)0.1mm ~ 12mm |

| Rapid power cross feed approx. | Manual (H Model) 1100mm/min (60Hz) 900mm/min (50Hz) |

| Cross feed on hand wheel 1 rev | 5mm |

| 1 gra | 0.02mm |

| Rapid power head elevation | 550mm/min (60Hz) 450mm/min (50Hz) |

| Vertical feed with MPG 1 rev | 2mm |

| 1 gra | 0.01mm (stand) / 0.005mm (with AD5) |

| Auto down feed (Option) | 0.001mm ~ 0.999mm/time |

| Wheel speed 60Hz/50Hz | 3500rpm (60Hz) 2900rpm (50Hz) |

| Wheel dimensions | 180 x 13 x 31.75mm (max. 200 x 20 x 31.75) |

| Spindle motor | 2HP |

| Hydraulic pump motor | 1HP |

| Auto. Cross feed motor | 1/5HP |

| Rapid head elevation motor | 1/5HP (Optional) |

STANDARD EQUIPMENT |

| Grinding wheel and wheel flange |

| Flange extractor |

| Wheel balancing arbor and base |

| Wheel dresser with diamond |

| Levelling screws and plates |

| Tool box and tools |

| Working light |

| Manual |