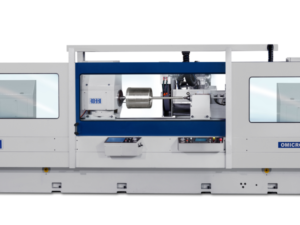

DESCRIPTION & SPECIFICATIONS

High precision and accuracy with a 250 x 500mm capacity, the Perfect X25 with Cross & Vertical is driven by AC servo Motor. LCD touch screen panel (HMI Interface) and PLC controller. Self-induced graphically-controlled interface with intuitionally finger-touched buttons makes the control of the machine easier and allows an operator to input parameters through screen-touched buttons easily. The Multi-functional grinding and polishing dressing parameters can reduce operators’ technical threshold.

SPECIFICATION |

|

| Table size | 250 x 500mm |

| Maximum distance from centre of spindle to table | 500mm |

| Maximum table travel | 510mm |

| Maximum cross travel | 255mm |

| Rapid power up/down | 550mm/min |

| Rapid power cross feed | 900mm/min |

| Table speed | 3~25m/min |

| Minimum feeding setting | 0.001mm |

| Spindle motor | 2.25kW |

| Motor for vertical feed | 0.75kW AC Servo motor |

| Motor for cross feed | 0.75kW AC Servo motor |

| Hydraulic motor | 0.7kW |

| Grinding wheel speed | 3500rpm (60Hz) |

| 2900rpm (50Hz) |

MACHINE EQUIPPED WITH:- |

| 10″ (16:9) HMI touch screen panel |

| Auto downfeed system (PLC) |

| Grinding mode: surface, criss cross, plunge and pitch (same depth) |

| Auto longitudinal and crossing stroke adjustment |

| Stepless variable proportional valve hydraulic system |

| Vertical and cross feed travel driven by AC servo motor + MPG |

| Linear guide ways for cross and vertical feed |

| 2.25kW spindle motor inverter |

| Auto dressing and compensation function (diamond dresser on the table) |

| Position display (cross feed and vertical feed) |

| Semi enclosed splash shield (right side open) |