DESCRIPTION & SPECIFICATIONS

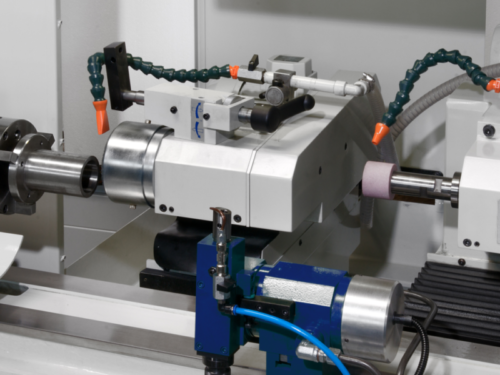

ROBBI IGR 600 Internal Grinding Machines are available as CNC & Semi Automatic versions. Maximum internal grinding diameter of 250mm. Siemens control.

SPECIFICATION |

ROBBI IGR 600 | |

| Maximum internal grinding diameter | 250mm | |

| Height of centres over table | 180 / 230mm | |

| Maximum cantilever weight (150mm from spindle nose | 80Kg | |

| Maximum distance between headstock & grinding spindle | 1200mm | |

| Maximum diameter of grinding spindle | 120mm | |

| Maximum table swivel | +8 deg / -4 deg | |

| Table speed | 0-4000mm/min |

CNC & SEMI AUTOMATIC VERSIONS AVAILABLE

CNC (SIEMENS 840DI) & SEMI AUTOMATIC (T6 PLC) VERSIONS AVAILABLE

ROBBI T6 PLC VERSION INCLUDES:

- Control panel SIEMENS TP 700 for easy programming of grinding cycles

- Wheelhead and table position visualized on operator panel

- Programmable grinding cycles: plunge and pass

- Program up to 12 different diameters, in a single grinding cycle

- Possibility to update the operative panel, with the correction of each diameter

- Manual grinding cycle, with stop of the grinding wheel feed once the programmed diameter has been reached

- Automatic grinding wheel dressing cycle with compensation of all the grinding dimensions

- In-process measuring gauge and gap control systems (Option)

AUTOMATIC GRINDING CYCLES, PLUNGE AND PLUNGE AND PASS WITH PARAMETERS:

- Stock removal – rough and finish

- Automatic increments – rough and finish, for pass grinding cycles

- Automatic feeds – rough and finish, for plunge grinding cycles

- Dwell – table inversion

- Sparkout time

- Sparkout pass

PRECISION DEGREE

ROBBI grinding machines are built in accordance to the international precision Standards ISO 2433. The table movement linearity is guaranteed within a maximum deviation of 0,002 mm/m. Surface finish degree: 0,2 Ra µ (**). The obtainable grinding roundness is (with live spindle) 0,4 µ (**)

(**) For a test workpiece ground in our factory during machine testing.